North America Series

Live Online Interactive Masterclass

3-Days Maintenance & Reliability Best Practices with SMRP BOK Workshop

Next Batch: Apr 24th to Apr 26st 2024

Upcoming BatchesThis is a 3 days of highly advanced & intensive program which focuses on boosting your understanding of the world’s Best Practices in the Maintenance & Reliability Space of your workforce

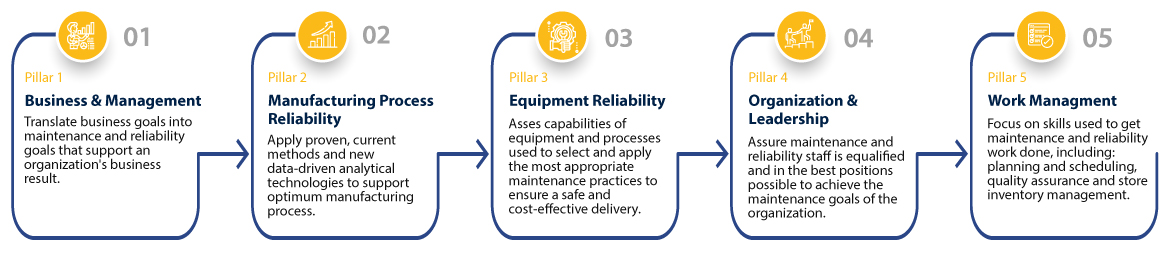

Through this Masterclass, we focus on the five pillars of the Society for Maintenance and Reliability Professionals, also known as SMRP’s Body of Knowledge:.

Source (SMRP website)

The Society for Maintenance & Reliability Professionals (SMRP) is a not-for-profit professional society formed by practitioners to advance the maintenance, reliability and physical asset management profession.

The CMRP is the only certification program of its kind accredited by the American National Standards Institute (ANSI), which follows the globally-recognised ISO standards for its accreditation purposes.

The test is a thorough examination of a broad scope of expertise measured against the universal standard. It was developed to assess professionals’ aptitude within the five pillars of the SMRP Body of Knowledge (BoK), which include: Business & Management, Equipment Reliability, Manufacturing Process Reliability, Organisation & Leadership, and Work Management

The course is designed specifically for individuals participating in or aspiring to the following

All of our training is led by some of the world's top minds in their respective fields worldwide

Our courses are designed by the same trainer that delivers them hence, guarantees best of the breed curriculum within the training

6 Months unfettered access to recorded training for maximizing your learning outcome of the program

Support in your journey to becoming a world-class Maintenance & Reliability expert, even after training ends

This course will help and Improve your understanding of the best practices of Maintenance and Reliability that our trainer has gathered with over 30+ years of combined experience:

AW Schultz is a recognized thought leader on maintenance work management, an entrepreneur, a best-selling author, a sought-after strategist, an educator, and a consultant with global engagements.

With over 25 years of experience in maintenance and reliability, he is routinely called upon to offer guidance to senior executives and those in the maintenance and reliability community to improve their organizations' overall efficiency. Have shown value inability to provide strategic insight and tactical analysis and convert these thoughts into reality by successful engagement and execution.

AW believes that to be great as an educator, you must create a safe, interactive, collaborative environment that promotes problem-solving and critical-thinking skills. The right atmosphere encourages students to present their opinions while respecting the views of others. By giving a voice in his training events, they benefit from peer-peer learning and enrich the training material with personal experiences and knowledge so that they can take responsibility for their education and, therefore, enhance the integration of their new insight into their own organization.

To teach students and implement strategies that create a collaborative application of knowledge to new situations. AW believes these practices help employees become ready and able to utilize their expertise and improve the overall organization they support.

An expert in building infrastructures, he emphasizes the cornerstones for success: the engagement of people and processes instilling a leadership culture as part of the company's DNA. His end goal is to help create high-performance individuals working in high-performance teams for high-performance organizations.

AW holds two bachelor's degrees in Agriculture Systems, Manufacturing and an MBA. He is a Certified Maintenance Reliability Professional, Project Management Professional, and a Master Black Belt in Six Sigma. AW resides in Dallas, Texas, with his wife, son, and daughter.

AW Schultz with 20+ years’ of experience as an educator has facilitated the learning of others. He has been an educator, an innovator and an enabler for his learner’s.

AW Schultz as a great trainer is focused on “YOU” As is the case with a educator, his primary goals has always been to be focused on “YOU” and “YOUR SUCCESS”.

AW Schultz is in the business of making the learning happen. AW Schultz with his focus on the outcome keeps imploring himself with a simple question-“What is the outcome from this learning session from my trainees?”

Review of Day 2

Creating a Master Plan to transition your organization to a higher level of reliability and maintainability along with a Maintenance Dashboard

Key Takeaways from this training

World Class Maintenance (Alumax Mt Holly – John Day PE, one of the founding members of SMRP)

It was nostalgic, brought back so much that I knew in a different light so to speak.

Few Top Things - RCM, PMO and Benchmarking (Typical vs World Class). It is a great course to improve plant performance and reliability. A must have course for all maintenance personnel.

Trainer highly skilled, knowledgeable and experienced, went beyond the content and scope of CMRP certification exam and shared his personal knowledge and technical skills relevant for everyday maintenance tasks. I obtained knowledge in asset strategy amangement and maintenance work management which are very useful in my current organization and future organizations as well. Exceeded expectation

Wonderfully put together and executed.

Please fill in the form below to get more information on registration and a member of our team will be in touch with you in less than 24 hours

The training’s key goal is to help Maintenance & Reliability professionals learn about the world’s best practices and methodologies in the area of Maintenance & Reliability for improving their overall M&R, Asset Management Strategies in their profession.

The course will help professionals desiring to obtain certification as a Certified Maintenance and Reliability Professional (CMRP) by improving their knowledge of the five pillars of M&R best practices.

So, any individuals who are participating in or aspiring to the following should take the training

I am not interested in CMRP, can it still be beneficial for me?

Certified Maintenance and Reliability Professional (CMRP) focus

The CMRP is very focused on the skills required to effectively manage and sustain an effective maintenance and reliability program for equipment and facilities. The body of knowledge is based on five pillars of effectiveness.

The training is completely Live Online Interactive Classes. You can choose self paced mode, if you’re unable to attend the Live Classes

Granted by the Society of Maintenance and Reliability Professionals (SMRP), the CMRP trains and evaluates professionals on business and management, manufacturing process reliability, equipment reliability, organization and leadership, and work management.

There are many benefits to becoming a CMRP. For instance, the CMRP certification can help individuals advance in their careers. In fact, some employers place the CMRP certification as a requirement when hiring employees. Also, when you become certified, you gain membership into the SMRP and access to a ton of resources on maintenance and reliability.